Nowadays, the fashion industry has many difficulties relating to the production process. The production style is still old fashioned, but recent fashion styles requests more complicated and delicate operations.

How can the fashion industry change in order to adapt and enable smooth product production? Ohashi Megumi from Apparel Play Office advocates a new method called ‘Apparel 3D Modelling’ using 3DCG and VR for the production process.

This is a 3D project by apparel pattern makers, and if it succeeds, the production cost will be drastically reduced. So, how can 3DCG and VR technology be used for apparel production? I interviewed Ms. Ohashi on this topic.

【Profile】

大橋めぐみ OHASHI Megumi

2001/3 Graduate from Esmodjapon. 2001/4 Started work for FLANDRE.K.K. Worked as a pattern designer for ‘ef-de’, ‘YVON’, ‘CLEAR IMPRESSION’ and more. 2005/11 Started work for P/X K.K. BIGI group. Worked as pattern designer for ‘et vous’, ’ev by et vous’ 2009/8 Started work for Tamurakoma K.K. Took charge for more than 20 brands.

Using 3D Modelling to Solve Apparel Production Problems

―I find it unique that while you are working as a pattern designer, you also do 3D modelling. Was there a reason why you started 3D modelling?

Ms. Ohashi: I first became interested in 3DCG and VR in 2016, when such technology started to show up at innovation festivals. In 2017, I read a article by Sapeet K.K. on how they are using a system to enable customers to try on clothes using a monitor.

But they were only using this system for sports uniforms back then, and there were no samples for fabric cloths. I wondered why, and came to the conclusion that making patterns for fabric cloths needs expert knowledge. This was when I thought that pattern designers could take a part in the 3D industry.

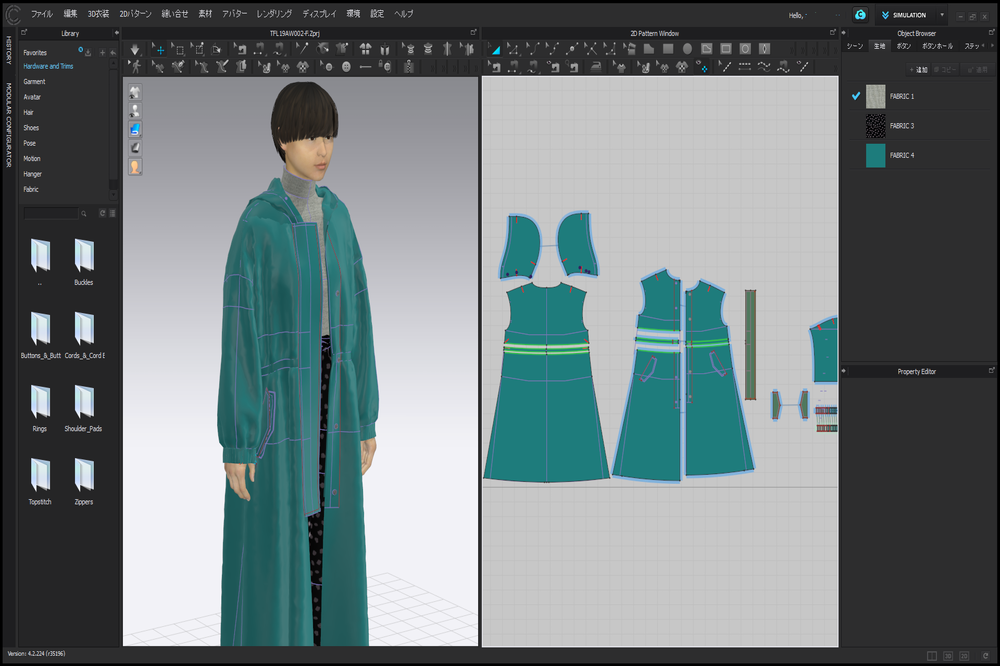

I researched which kinds of software were being used, and started to use CLO3D(※), a software that can create 3D simulations from fashion sketches.

※CLO3D: A 3D software that can create 3D models from 2D fashion sketches. It is useful since users can easily visualize what the design pattern will look like, and also because users can smoothly create 3D models.

A Japanese CAD company called YUKA&ALPHA recently started to distribute this software, so I directly asked questions to them too.

―How was CLO3D?

Ms. Ohashi: I’m not too bright with technology, but since I was able to learn the basics from an instructor, it wasn’t too hard to use. There are many 3D artists that are using CLO3D, and I hear that it is simple to use compared to other 3D designing software.

―How familiar were you with technology beforehand?

Ms. Ohashi: Many people from the apparel industry are not familiar with this technology. I personally had to learn how to use CAD software for my job, but I am not used to this technology either.

In order to start this new fashion tech business, I needed to learn about VR and CLO3D. I went to a school for studying.

―What merits did you find using CLO3D for apparel production?

Ms. Ohashi: I have worked for 10 years creating sample pattern designs for different brands at a apparel company. Sometimes, for 1 product, we create 10 designs for proposal.

But there is only room for one product for that project, and the remaining 9 designs will be never used. Even if the business talk goes well, and the brand takes more than 1 design, it is usual that more than half of the designs are not used.

When showing the sample designs, it is hard to imagine the finished product from a 2D sketch. We usually need to create a sample product and show it directly.

But if we create too many samples, many unused samples have to be thrown away.

―It must be sad when the design is not used, especially when you have put effort in creating a sample product……

Ms. Ohashi: Yes, it is…… The designers have to create designs without knowing if it is going to be used, and pattern designers create sample products that may be thrown away. The personnel expenses cannot be ignored too.

We create the samples in China right now, but it takes 10 days to 2 weeks creating the sample product, and there is a loss not only for the materials, but time too.

Another problem is that 10 years back, products were created in central China. But since wages have increased, companies are using factories in the countryside, meaning it is taking more time to get the finished product.

But in the new future, those factories will be too expensive to use too, so companies will start to use ASEAN or Bangladesh factories. This means even more time is going to be needed.

From the designer side, it will be best if the due date of a product will be about 3 months, but the apparel brand company wants to research as much as possible to seek customer needs, and want the due date around 2 months. But using Bangladesh or India factories means that it will take at least 4 months.

By using 3D models for sample products, we can shrink this time to 3 months. Considering the future, I believe that this is the way to go.

If designers can show 3D models to let the apparel brand decide which designs the brand wants to see as a real sample, many losses can be made smaller.

―How is your business using 3D models right now?

Ms. Ohashi: We are mostly visiting potential customers right now, but 2 companies are already using 3D model samples. Some companies that are interested in using 3D models for fashion are contacting us too.

How Fashion and Technology Will Merge and Create New Ideas

―You also have created VR scenes with STYLY using CLO3D-made 3D models. How do you make these?

Ms. Ohashi: First, I import the CLO3D-made models to Unity to adjust the colors, then import them to STYLY. But after adjusting in Unity, the touch of the fabric changes, so if I could import to STYLY directly, it will be better.

―What do you think about fashion exhibits or shows using VR?

Ms. Ohashi: I originally wanted to make the avatar walk around like a fashion show in my scene, but the data became too huge.

I gave up for now, and added a video instead.

This scene was made as a collection exhibition, but my goal is to create a VR scene where the model walks around as in a fashion show, so I hope to communicate with Psychic VR Lab in order to reach it.

―I personally hope that VR creators could take a part in future VR fashion shows.

Ms. Ohashi: At TFL, we talked about how Vtubers were showing and promoting products and clothes. I too think that if Vtubers could wear clothes and promote brands at a VR fashion show, it will be very interesting.

I know that changing clothes is technically difficult for Vtubers right now, but I am pretty sure that simply showing products and describing them will be entertaining. Maybe sometimes with a wicked tongue?

―A wicked tongue! That will certainly be entertaining.

Ms. Ohashi: Another thing I want to do is to create a VR shopping mall. For example, a store with products from various sports makers, or a room with entertainment rides, and so on.

―I see a world full of variety that must be fun to roam.

Ms. Ohashi: I think that customers will have fun looking at products that way. VR is a technology that many women find unfamiliar, so I believe that we have to try from many perspectives in order to get customers interested.

These are the Reasons That Many Losses are Created at Apparel Production

―Can you tell me how much losses you can prevent or lessen by using 3D models?

Ms. Ohashi: Making products cheaper with 3D models will not be possible in the near future. But the cost for creating samples and the whole production period will become shorter by this technology.

But there are emerging new problems inside apparel brand companies and apparel company OEM and ODM departments.

―What kind or problems?

Ms. Ohashi: Going back a little, when I was hired as a new employee, it was in the middle of an employment ice age. There were only half the number hired compared to 3-4 years earlier.

But that was still better than after 1 year, when fast fashion was first introduced to Japan. This caused apparel brands and companies to go into complete chaos.

I was luckily already working then, but apparel brands experienced very bad performance and started to not hire new employees. Quite the contrary, they started to fire current employees.

As many famous brands downsized their designing departments, they came to the conclusion that they are better off outsourcing.

Since then, tech and knowledge stopped being passed on inside companies, and apparel brands are no longer training designers.

―Wait, can apparel brand companies fire designers and still continue business?

Ms. Ohashi: Most people find this fact surprising.

Apparel brand companies no longer have designers or for that matter pattern designers. They are now buying designs from outside. There are companies specialized in selling designs, ODM/OEM companies, and outsourcing became very common in the apparel industry. There are brands that have 0 designers now.

―I guess that leads to designers creating numerous samples, and apparel brands choosing a few from there…

Ms. Ohashi: That’s right. In order to compete with fast fashion, brands lowered their prices. In order to cut costs, brands fired designers and chose to outsource. But this leads to a new problem.

When designers show samples to apparel brands, the variation becomes much smaller, and sometimes similar samples are created. This resulted in similar products created by different brands, and the characteristic of each brand became much weaker.

The price becomes much lower, the designs are all outsourced so there are only similar clothes in shops. Customers will think that if they are similar, the cheaper the better. The fashion industry was caught in this negative spiral.

―Which leads to the current production process.

Ms. Ohashi: Yes. The unit price continues to decrease, but apparel brands have to create more revenue each year. To achieve that, they have to sell more. But they have to create more clothes for that. Nowadays, it is really hard to anticipate if a product will sell or not. Many fashion magazines predict the trend, but even experts cannot foresee the future now.

In the past, it was much easier. For example, everyone was interested in what Namie Amuro was wearing, and followed suit.

―Yes, celebrities were the influencers back then.

Ms. Ohashi: That’s right. But now, young generations are more interested in Instagram, and there are much more variety with influencers.

Sellers are not confident in new products, and have to try and create many products to reach their sales goals.

―I hear that in the past, there were promotions to the mass, to everyone. But nowadays, companies have to adjust to individual needs.

Ms. Ohashi: In the past, apparel brands were the ones creating the trend. But now, the consumers are the ones creating the trend. Unsure brands could not create pricey products, and created cheap products as much as they could.

But some time has passed, and some customers are beginning to become interested in custom suits. I believe that this trend shows that even if fashion becomes more expensive, customers will just want clothes that really suit them.

How Technology Changes Work Life Balance

―Can 3D technology make a comeback for designers and pattern designers?

Ms. Ohashi: From the pattern designer side, the working conditions have increased in diversity. When I started working, most pattern designers did not marry. One reason is because the salary was good, and another was that everyone loved their job.

But, when they did get married and decided to have a child, they had to leave.

―Is that because it is too difficult to raise a child and work at the same time?

Ms. Ohashi: Yes. Recently, many companies have started to permit working short time, but pattern designers have so many work and have to think about due dates all the time. They have something to do everyday and have no extra time.

So, it is very hard to stop work to go and pick up your child from school, or take a day off when your child needs to go to the hospital.

―I see….will 3D modelling change such environments?

Ms. Ohashi: In the past, I had friends that stopped working as a pattern designer after marriage. But even so, they wanted to continue working in the fashion industry, so they changed to departments like inspection. But by using 3D software like CLO3D, I believe that pattern designers will be able to work from home.

Of course, the designer will have to study first, but using CLO3D means that the designer can perform work from home at a very cheap cost. Without 3D software, pattern designing needs many machines and space, taking about 800,000 to 1,000,000 yen. CLO3D only needs a single computer and a software license.

―That is a drastic change.

Ms. Ohashi: Yes it is. Since the job is very similar to pattern designing, and previous pattern designers can use their specialized skills, many ex-pattern designers are interested in our business. If they can work from home, they can still work while raising children.

If the designer wants to work from home, we can give them work that meets their skills. Pattern designing is very hard work, and we can also hire people who had to leave work because of reasons such as sickness.

―The fact that they only need a computer and connection to the internet is huge, I guess.

Ms. Ohashi: There are people who returned to their homes in the countryside after ruining their health. Using this technology enables people to work from outside Tokyo, and provides many pattern designers a comfortable change to their lifestyles. This is one of my goals too.

―This will be my last question. How are you introducing 3D modelling and VR technology to fashion companies?

Ms. Ohashi: VR, and 3D technology enables designers to work from home, and can also be used as a communication tool. The designer does not need to travel everyday to the office, meaning travel time can be reduced also.

It can also be used for study meetings with apparel associates working in the countryside, and they will not need to travel to the main office each time.

I hope designers, pattern designers, and other workers can use this technology and be able to have different lifestyles while working.